Building a Mach-Zehnder Interferometer

What is a Mach-Zehnder Interferometer?

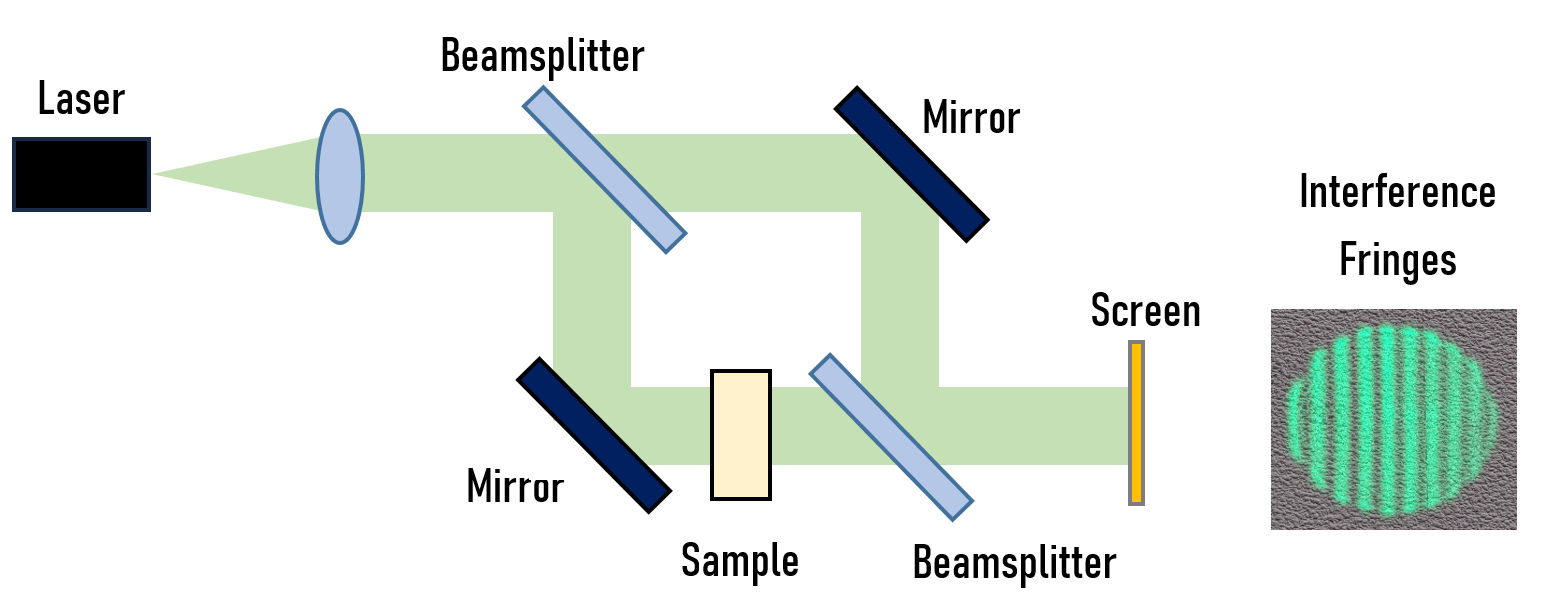

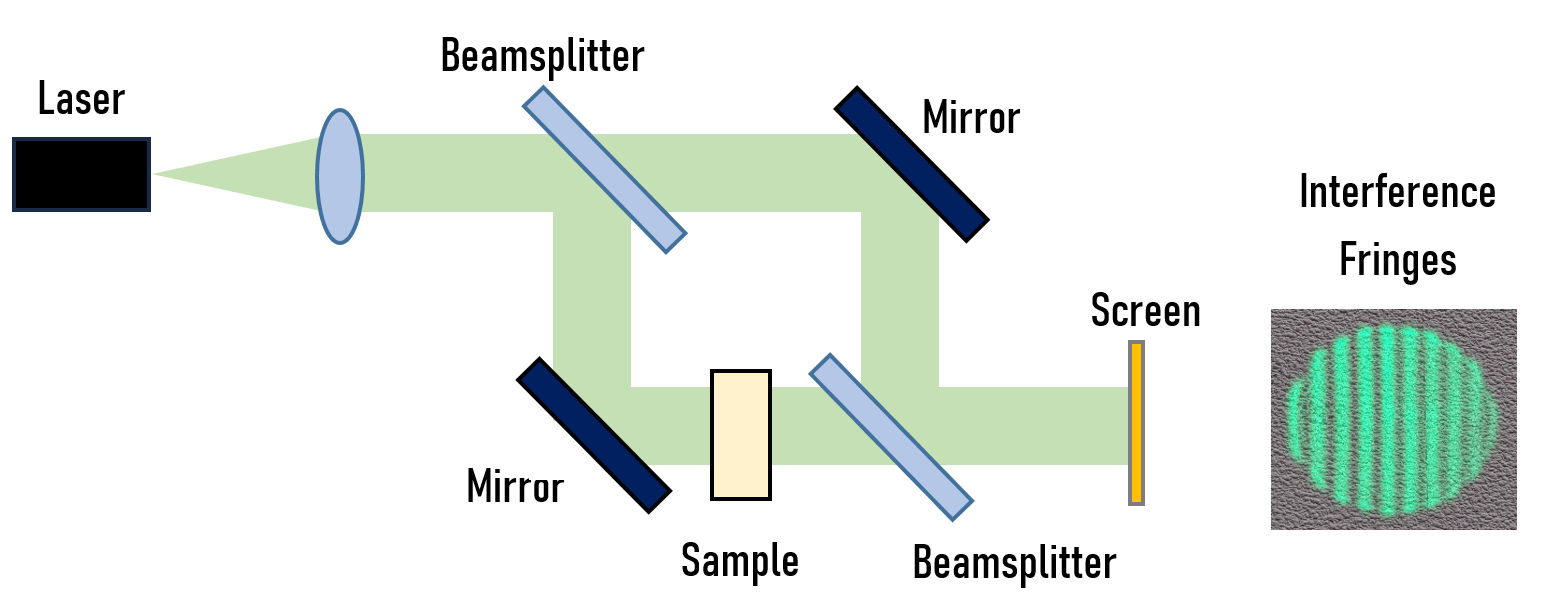

Mach-Zehnder interferometers are simple interferometric instruments that measure the relative phase shift between two collimated light beams. This phase shift can be used to determine small displacements, the transmitted wavefront error of transmissive optics, the refractive index of transparent materials, air flow in wind tunnels, and more.

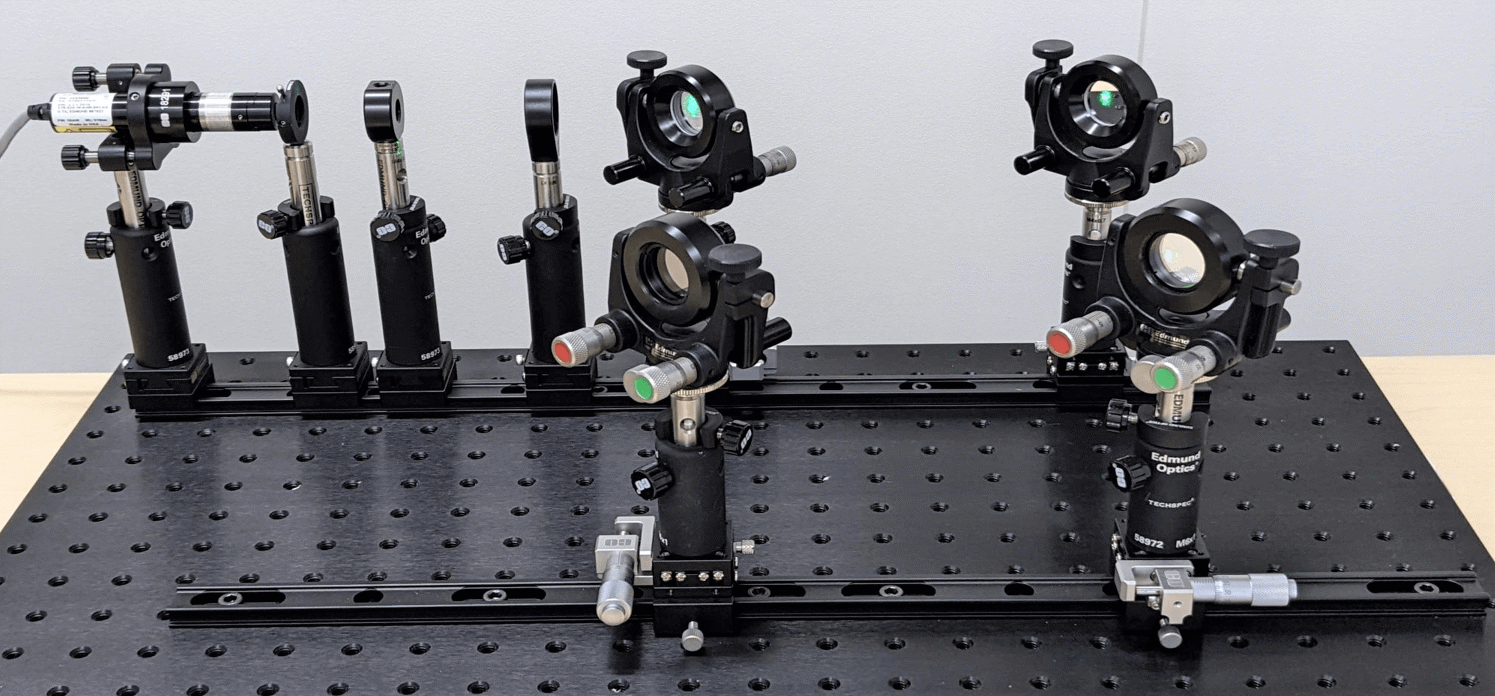

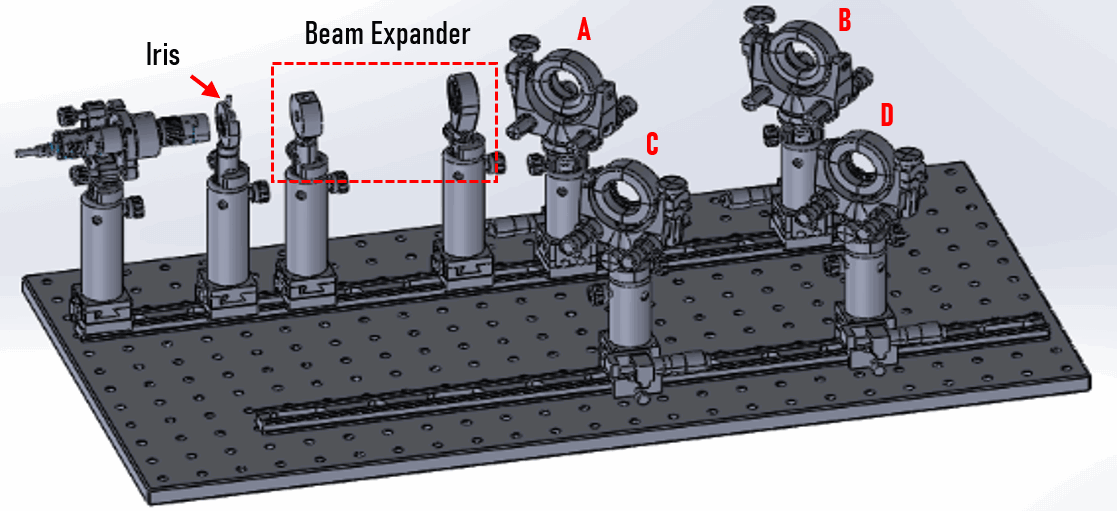

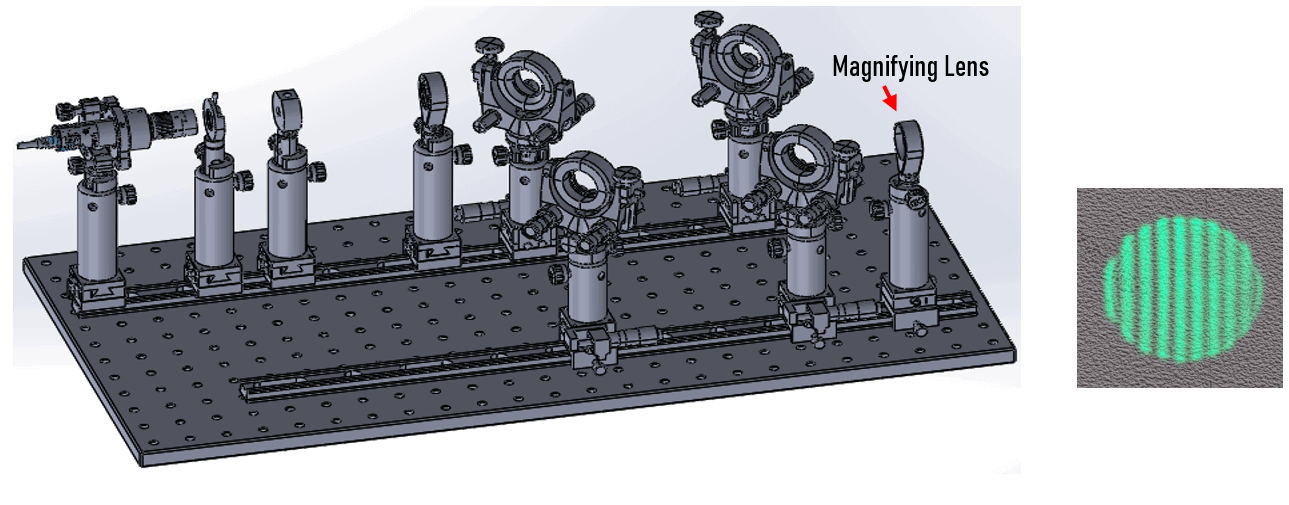

Mach-Zehnder interferometers consist of a coherent light source like a laser, two beamsplitters, and two mirrors (Figure 1 and Figure 2). First, the light source is split into two paths using the first beamsplitter. The two beams each have the same optical path length, which is the distance traveled multiplied by the refractive index of the media they travel through. Each beam reflects off of a mirror and is recombined by the second beamsplitter. If there is a difference in the optical path lengths of the two beams that is less than the coherence length of the light source, interference fringes will be generated. Because the coherence length of a source can be extremely short, precision components and alignment are crucial. A sample can be measured by being placed in one of the beam paths. The resulting optical path length difference can be measured by observing the change in the interference fringes.

Figure 1: Typical optical schematic of a Mach-Zehnder interferometer

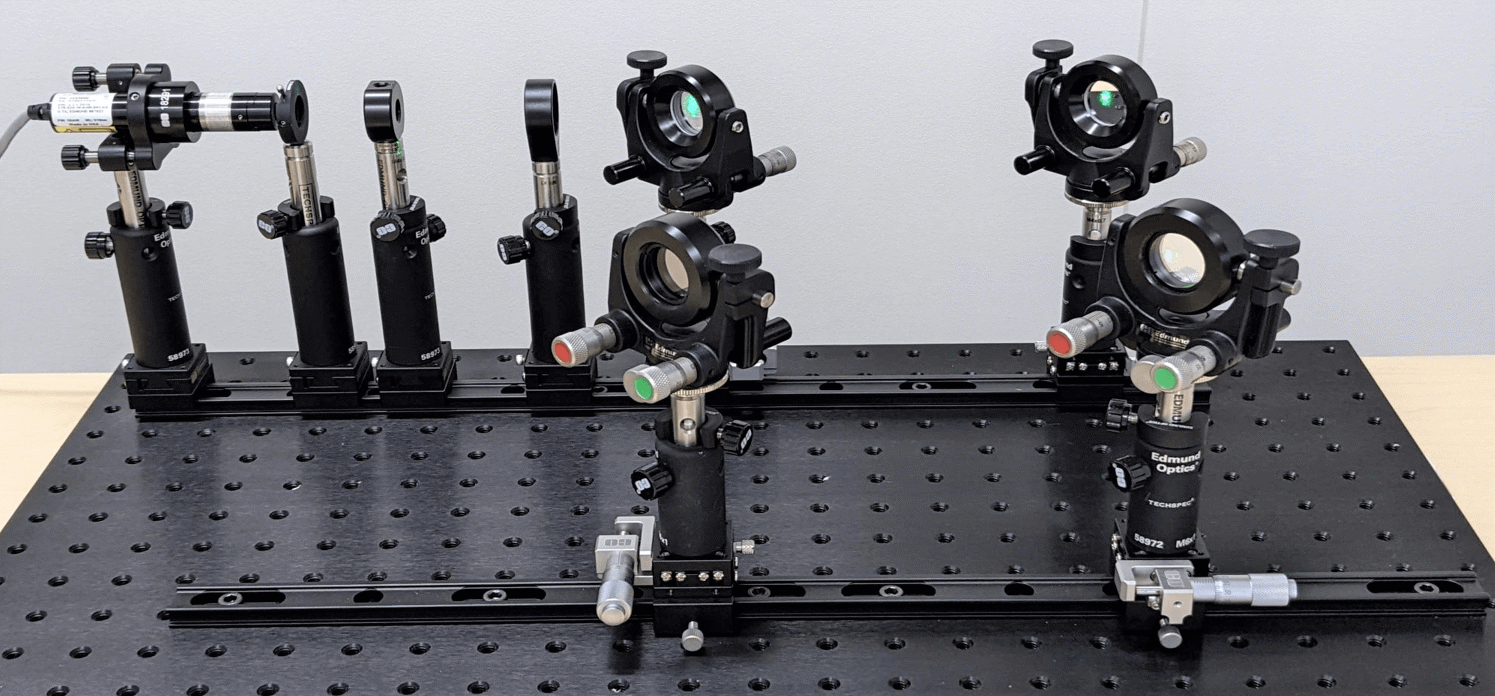

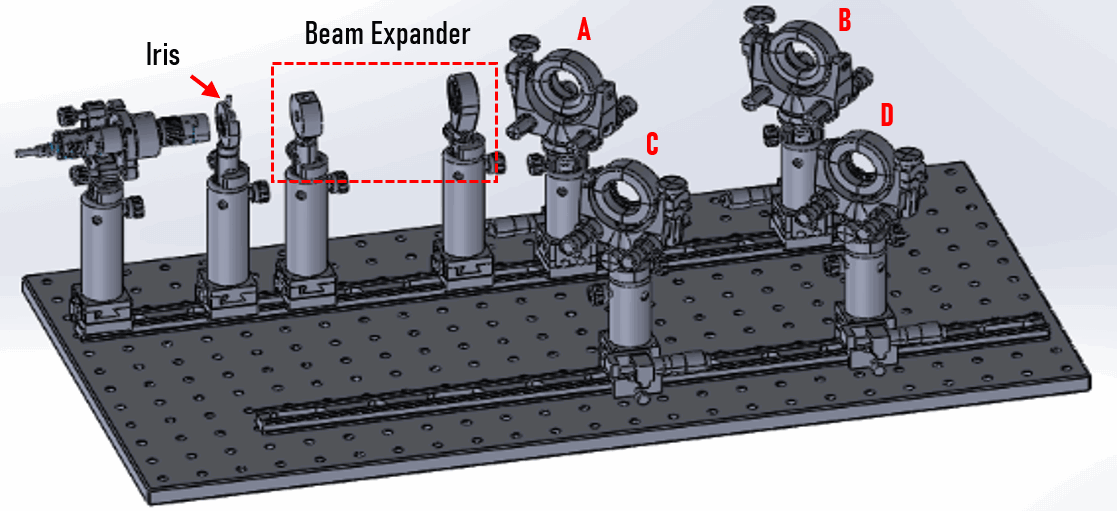

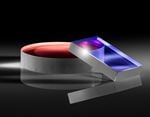

Figure 2: Assembled tabletop Mach-Zehnder interferometer system constructed out of off-the-shelf components from Edmund Optics®

Assembling System using Off-the-Shelf Components from Edmund Optics®

A system like the one shown in Figure 2 can be assembled by following the guide below. \

Sub-Assemblies

Each optical sub-assembly can be added to a table-top breadboard and easily slid along the optical axis via optical rails. The small linear motion stage placed on the carrier of the optical rail makes it easy to make fine adjustments in the optical axis direction or the orthogonal direction.

Optical Base

| Stock # |

Description |

Quantity |

| #54641 |

600mm x 300mm, Breadboard |

1 |

| #54929 |

500mm Length, Compact Optical Rail |

2 |

Light Source

| Stock # |

Description |

Quantity |

| #86848 |

Coherent® StingRay™ Laser Diode Module 1231490 | 520nm, 5mW |

1 |

| #59099 |

5V Universal Power Supply |

1 |

| #18291 |

E-Series 19.1mm ID Adapter |

1 |

| #15866 |

25.0/25.4mm Optic Dia., E-Series Kinematic Mount |

1 |

| #59760 |

63.5mm Length, M6 Stud, Steel Post |

1 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

1 |

| #58992 |

Post Collar |

1 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

1 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

1 |

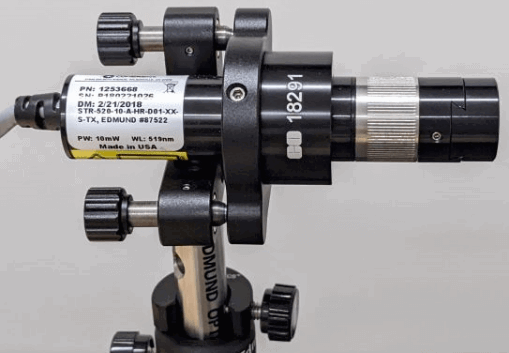

Figure 3: Light source sub-assembly

Iris Diaphragm

| Stock # |

Description |

Quantity |

| #53914 |

30.8mm Outer Diameter, Mounted Iris Diaphragm |

2 |

| #58963 |

2.5" Length, 8-32 Stud, Steel Post |

2 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

2 |

| #58992 |

Post Collar |

2 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

2 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

2 |

Figure 4: Iris diaphragm sub-assembly

Plano-Concave Lens Mount

| Stock # |

Description |

Quantity |

| #64552 |

6.0mm Optic Dia., Optic Mount |

1 |

| #48690 |

6mm Diameter x -15 FL, VIS 0° Coated, Plano-Concave Lens |

1 |

| #59760 |

63.5mm Length, M6 Stud, Steel Post |

1 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

1 |

| #58992 |

Post Collar |

1 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

1 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

1 |

Figure 5: Plano-concave lens mount sub-assembly

Plano-Convex Lens Mount

| Stock # |

Description |

Quantity |

| #13787 |

25.0/25.4mm Optic Dia., SM1 Thin Mount, M4 |

1 |

| #62573 |

25.4mm Dia. x 76.2mm FL, VIS 0° Coated, Plano-Convex Lens |

1 |

| #58953 |

63.5mm Length, M4 Stud, Steel Post |

1 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

1 |

| #58992 |

Post Collar |

1 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

1 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

1 |

Figure 6: Plano-convex lens mount sub-assembly

Projection Lens Mount

| Stock # |

Description |

Quantity |

| #13787 |

25.0/25.4mm Optic Dia., SM1 Thin Mount, M4 |

1 |

| #47917 |

25mm Dia. x -25mm FL, VIS 0° Coated, Double-Concave Lens |

1 |

| #58953 |

63.5mm Length, M4 Stud, Steel Post |

1 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

1 |

| #58992 |

Post Collar |

1 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

1 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

1 |

Figure 7: Projection lens mount sub-assembly

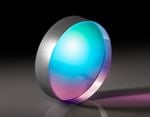

Gimbal Mount with Mirror (2set)

| Stock # |

Description |

Quantity |

| #54999 |

25.0/25.4mm Optic Dia., Precision Gimbal Mount |

2 |

| #64015 |

25mm Diameter Enhanced Aluminum Coated, λ/10 Mirror |

2 |

| #59759 |

50.8mm Length, M6 Stud, Steel Post |

2 |

| #58972 |

50.8mm Length, M6 Thread, Post Holder |

2 |

| #58992 |

Post Collar |

2 |

| #66393 |

30mm, Side Drive, Standard Top, 0.5" Travel, Metric Micrometer |

2 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

2 |

Figure 8: Gimbal mount with mirror sub-assembly

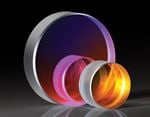

Gimbal Mount with Beamsplitter (2set)

| Stock # |

Description |

Quantity |

| #54999 |

25.0/25.4mm Optic Dia., Precision Gimbal Mount |

2 |

| #34413 |

25mm Diameter 50R/50T, VIS Wedged Plate Beamsplitter |

2 |

| #59759 |

50.8mm Length, M6 Stud, Steel Post |

2 |

| #58972 |

50.8mm Length, M6 Thread, Post Holder |

2 |

| #58992 |

Post Collar |

2 |

| #66393 |

30mm, Side Drive, Standard Top, 0.5" Travel, Metric Micrometer |

2 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

2 |

Figure 9: Gimbal mount with beamsplitter sub-assembly

Full Parts List

| Stock # |

Description |

Quantity |

| #54641 |

600mm x 300mm, Breadboard |

1 |

| #54929 |

500mm Length, Compact Optical Rail |

2 |

| #11164 |

30mm Length x 35mm Width, Compact Carrier |

10 |

| #16714 |

Dovetail Stage, 30mm SQ, Metric |

6 |

| #66393 |

30mm, Side Drive, Standard Top, 0.5" Travel, Metric Micrometer |

4 |

| #58972 |

50.8mm Length, M6 Thread, Post Holder |

4 |

| #58973 |

76.2mm Length, M6 Thread, Post Holder |

6 |

| #58992 |

Post Collar |

10 |

| #59760 |

63.5mm Length, M6 Stud, Steel Post |

2 |

| #58953 |

63.5mm Length, M4 Stud, Steel Post |

2 |

| #59759 |

50.8mm Length, M6 Stud, Steel Post |

4 |

| #58963 |

2.5" Length, 8-32 Stud, Steel Post |

2 |

| #86848 |

Coherent® StingRay™ Laser Diode Module 1231490 | 520nm, 5mW |

1 |

| #59099 |

5V Universal Power Supply |

1 |

| #15866 |

25.0/25.4mm Optic Dia., E-Series Kinematic Mount |

1 |

| #18291 |

E-Series 19.1mm ID Adapter |

1 |

| #53914 |

30.8mm Outer Diameter, Mounted Iris Diaphragm |

2 |

| #64552 |

6.0mm Optic Dia., Optic Mount |

1 |

| #48690 |

6mm Diameter x -15 FL, VIS 0° Coated, Plano-Concave Lens |

1 |

| #13787 |

25.0/25.4mm Optic Dia., SM1 Thin Mount, M4 |

2 |

| #62573 |

25.4mm Dia. x 76.2mm FL, VIS 0° Coated, Plano-Convex Lens |

1 |

| #47917 |

25mm Dia. x -25mm FL, VIS 0° Coated, Double-Concave Lens |

1 |

| #54999 |

25.0/25.4mm Optic Dia., Precision Gimbal Mount |

4 |

| #64015 |

25mm Diameter Enhanced Aluminum Coated, λ/10 Mirror |

2 |

| #34413 |

25mm Diameter 50R/50T, VIS Wedged Plate Beamsplitter |

2 |

Aligning a Mach-Zehnder Interferometer

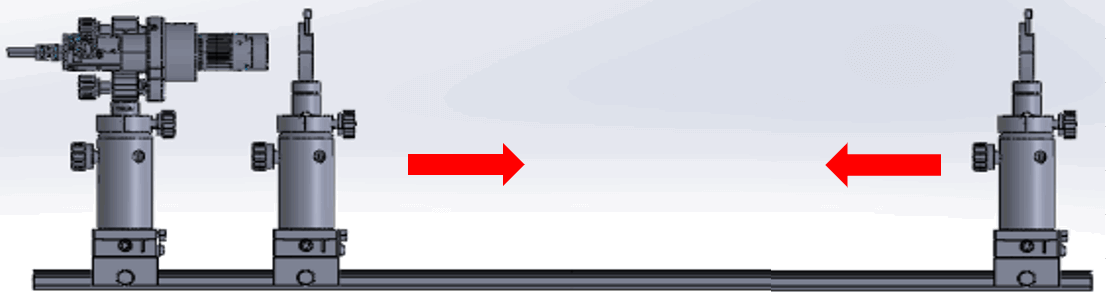

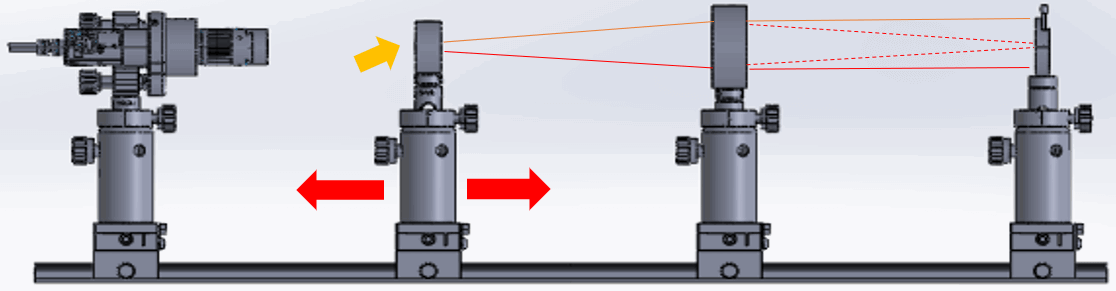

The laser, iris, and lenses must be aligned to the same optical axis. Ideally, the optical axis of these components should not change even if they are translated on the optical rail. A stage installed on the optical rail carrier allows for horizontal movement perpendicular to the direction of the rail.

- Installing the Laser Module

- Fix the laser module (diameter Φ19.1mm) to #15866 using the adapter (#18291).

- This makes it easy to adjust the laser angle.

- Adjust the angle of the mount so that the laser beam is parallel to the optical rail.

Figure 10: Installing the laser module

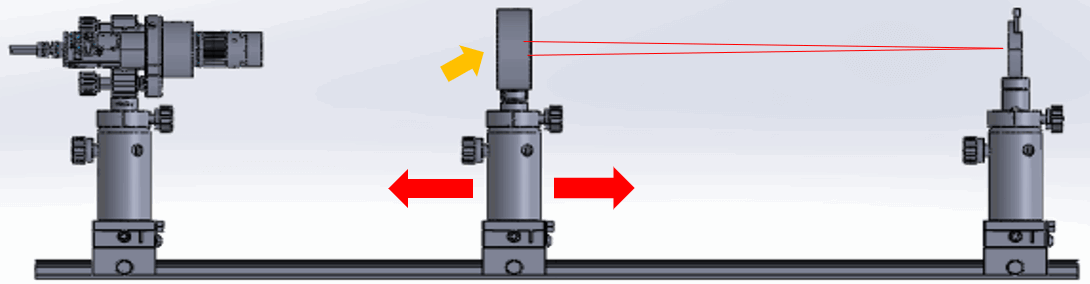

- Aligning the Laser's Optical Axis

- Use the iris sub-assembly to keep the center of the optical axis of all components of the system constant.

- Direct the laser onto the center of the iris.

- Slide the iris down the optical rail while making adjustments to the kinematic mount to keep the laser centered on the iris throughout the whole range.

Figure 11: Aligning the laser's optical axis

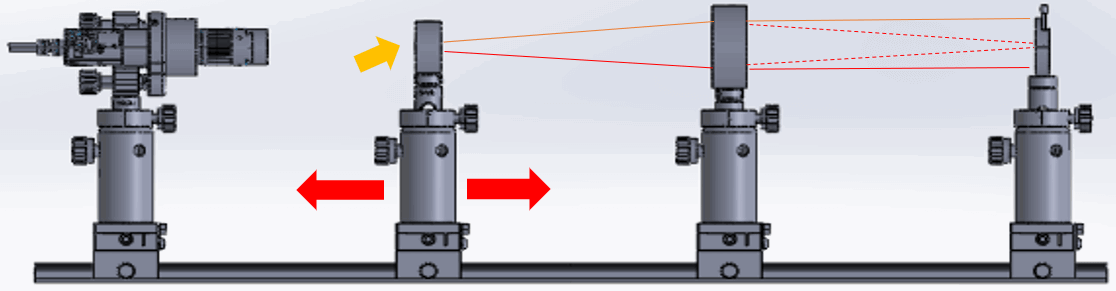

- Aligning the Plano-Convex Lens' Optical Axis

- Adjust the optical axis of a plano-convex lens with the long focal length while sliding the lens unit left and right.

- Use the post to adjust the height of the lens and use the dovetail stage to adjust the optical axis in the perpendicular direction.

Figure 12: Aligning the optical axis of the plano-convex lens with the long focal length

- Aligning the Plano-Concave Lens' Optical Axis

- Place a plano-concave lens with a short focal length in the optical path.

- Adjust the optical axis while sliding the lens unit left and right.

- Use the post to adjust the height of the lens and use the dovetail stage to adjust the optical axis in the perpendicular direction.

Figure 13: Aligning the optical axis of the plano-concave lens with the short focal length

- Positioning Lenses to Form Beam Expander

- The two lenses should be separated by the sum of their focal lengths. In this case, the separation should be 76.2mm – 25mm = 51.2mm.

- To learn more about pairing lenses to expand the diameter of a beam to a desired size, please visit our How to Design Your Own Beam Expander Using Stock Optics application note.

- Selecting coated lenses with low reflectance is important for avoiding stray light.

Figure 14: Positioning the two lens sub-assemblies in front of the iris to form a beam expander

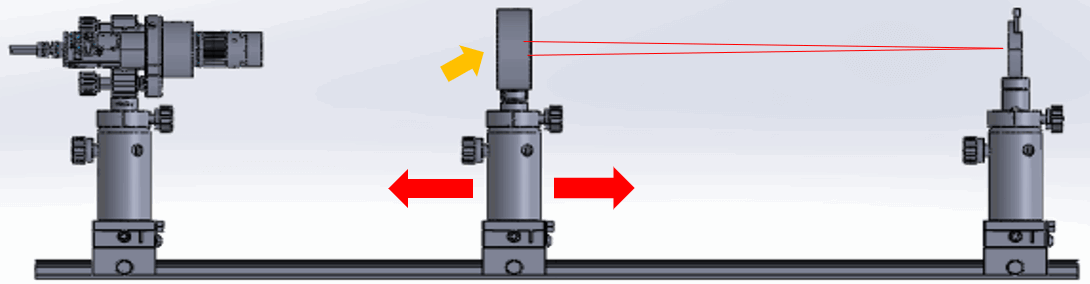

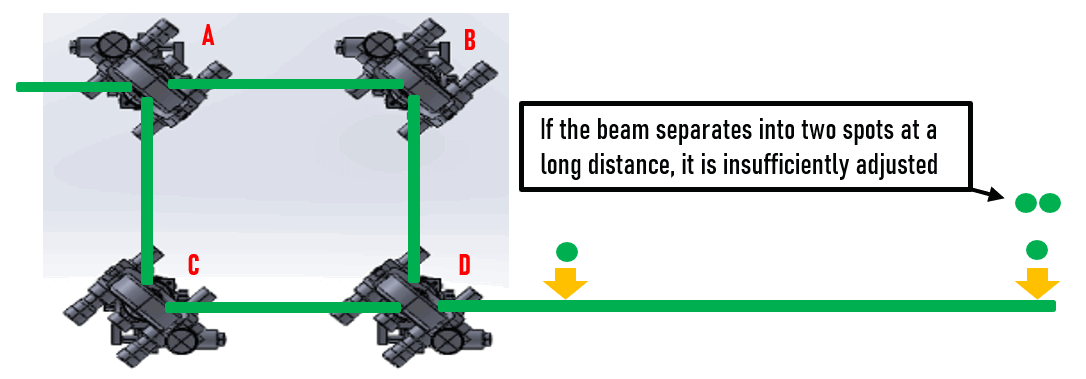

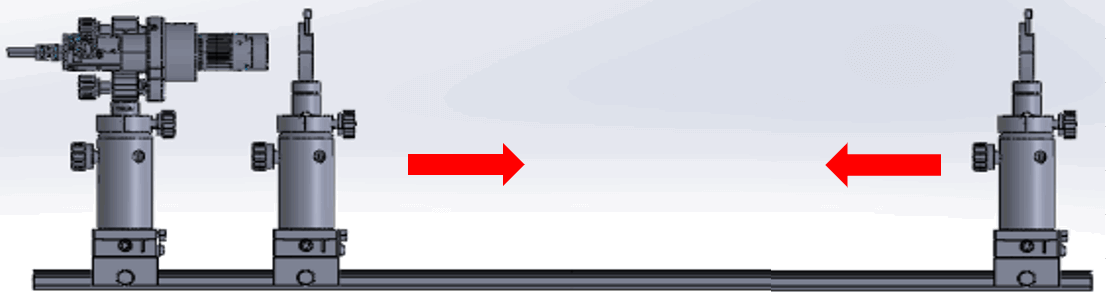

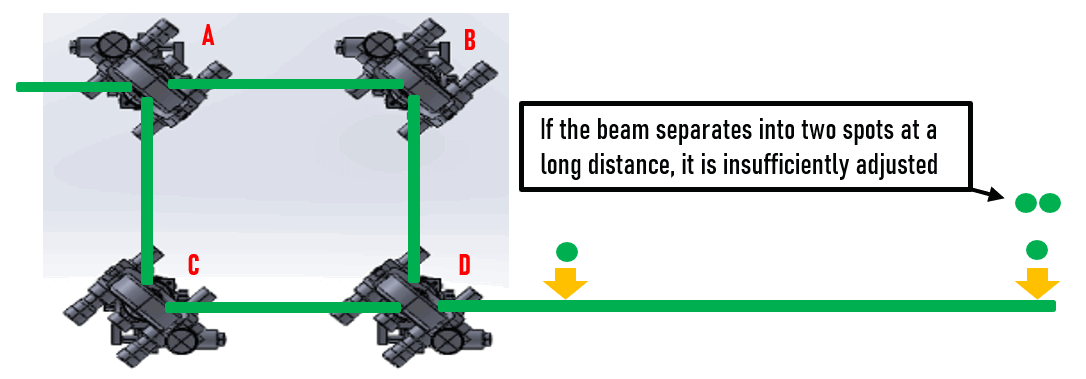

- Aligning Mirrors and Beamsplitters

- The two optical path lengths must be equal (or nearly equal) and the final beams must overlap to obtain fringes.

- A beamsplitter is placed in position A to split the laser into two paths and another beamsplitter is placed at D to recombine the beams.

- Adjust distances so that the optical path lengths of A-B-D and A-C-D are the same.

- Care must be taken to prevent the edges of the mirror/beamsplitter mounts from blocking the beam.

- The beam transmitted through D must overlap with the beam reflected at D.

- Adjust the mirror positions and angles so the two beams overlap right after D as well as further down the rail past D (Figure 15).

Figure 15: Aligning the mirrors and beamsplitters

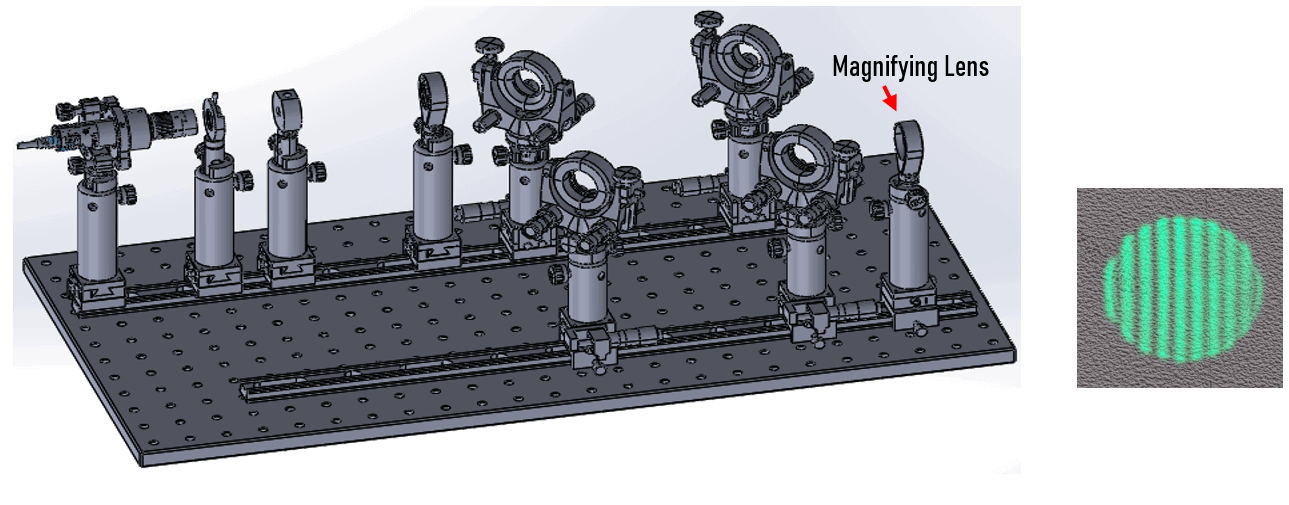

- Check for Interference Fringes

- Adding a magnifying lens after D can make it easier to identify fringes.

- The stage position on the optical rail and alignment of other components may need to be fine-tuned to obtain fringes

Figure 16: Final Mach-Zehnder interferometer setup constructed out of off-the-shelf components

More Resources

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act