|

|

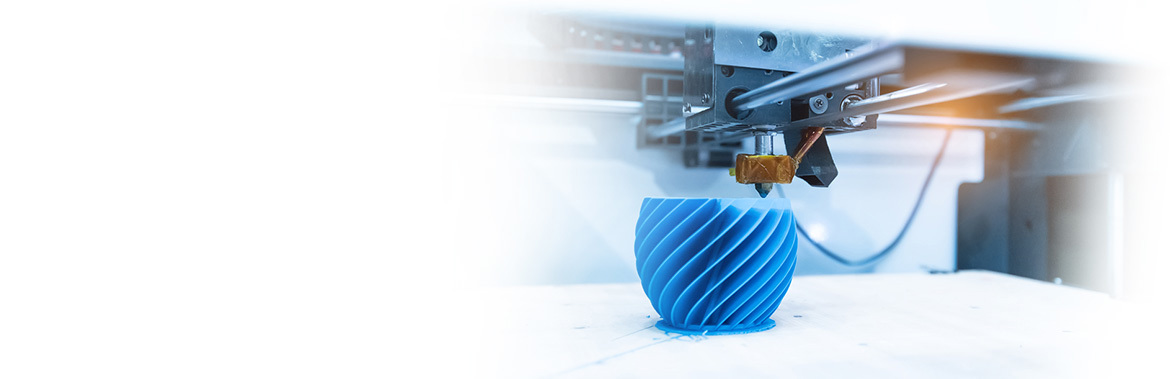

Enables rapid prototyping for dramatically reduced product development times |

|

|

Useful for creating tooling and fixtures for lab and production use |

|

|

3D models aid in selling product concepts to management and investors |

|

|

Used to make both polymer and metal parts |

Additive manufacturing and 3D printing have evolved over the past decade from curiosities to widely employed techniques for creating prototypes, and even actual production parts. Here you will learn the basics of how these technologies work, along with how they affect the photonics industry.

While there are a large number of distinct additive manufacturing and 3D printing methods, the processes described below are broadly representative of the technology. The most current techniques are variants of these basic methods.

Inkjet 3D printing is the most commonly employed 3D printing technology, and is a variation of the widely used inkjet printer. Except in this case, instead of ink the print nozzle extrudes a thin plastic filament that has been liquefied through heating. This can form a layer of material as thin as 0.1mm. Once a single layer has been formed, either the printhead is raised or the build platform is lowered by a distance corresponding to the layer thickness, and the process repeats. In some cases, the polymer material simply hardens as it cools. Alternatively, a photopolymer, which is hardened by subsequent exposure to UV light, can be employed.

Stereolithography is the oldest type of additive manufacturing where a build platform is put in a vat of liquid photopolymer and positioned to sit just below the surface. Next, a focused ultraviolet laser beam is scanned to trace out the required layer shape. The focused spot hardens the photopolymer selectively wherever it moves. The build platform is lowered vertically to the thickness of one layer, and the next scan is performed. This step is repeated until the entire object is formed.

In these techniques, a thin layer of powdered material is deposited on the build platform using a roller or wiper blade. In “binder jetting,” a print head then moves over the powder bed and sprays out a binding solution, which selectively fuses the powder material into a solid in the desired shape. Alternatively, in “powder bed fusion” techniques, either a laser or electron beam is scanned to melt the material, which then quickly resolidifies. The build platform is lowered and another thin layer of powder is spread over it; the process repeats until completion.

As additive manufacturing continues to become more affordable, effective, and widely used, it greatly affects the optics industry, and nearly every industrial sector. The following videos feature a panel of Edmund Optics engineering, design, and R&D experts sharing their insights on the wide-reaching impact of additive manufacturing.

This video covers the impact of additive manufacturing on the optics industry, different types of 3D printing, rapid prototyping, and recent developments in additive manufacturing. Watch now for insight on how to take full advantage of this growing technology.

This video covers the impact of 3D printing on IP protection, the future of additive manufacturing, and how additive manufacturing and automation influence the job market. Watch now to prepare for how 3D printing will potentially affect your career.

Like many manufacturers, Edmund Optics utilizes 3D printing methods to reduce product development cycle time and costs. This may involve 3D printing models of lens assemblies or mechanical components to get a quick read on form, fit, and function, which is often difficult to assess purely from CAD renderings.

Edmund Optics designers have utilized 3D printing for prototype packaging solutions in order to develop better ways to protect products during shipment. Packaging is often produced using molding or other techniques, which have substantial upfront tooling costs. Using 3D printing instead allows for effective and quick exploration of a wide range of potential solutions.

Edmund Optics also employs 3D printing methods to create tooling components for optics production in our manufacturing facilities. For example, specialized nozzles for optimized slurry spraying during optics polishing were 3D printed as conventional machining methods are more costly and time consuming for this application.

Can optics be 3D printed?

Can optics be 3D printed?

Can 3D printing be used to “copy” an existing object?

Can 3D printing be used to “copy” an existing object?

Sometimes an existing three-dimensional object can be scanned and then reproduced using 3D printing. However, scanning will only copy the object’s external shape, not its internal components. Therefore replicating any complex piece of machinery would require disassembling it and scanning in each component individually. Depending upon the object and the 3D printing technology utilized, this might not necessarily deliver parts with the precision required to reproduce the original object’s functionality.

Can 3D printing be used to repair existing parts?

Can 3D printing be used to repair existing parts?

Yes - a form of additive manufacturing called directed energy deposition (DED) involves introducing metal in powder, wire, or strip form on an existing metal part, and then using a laser to melt the powder and fuse it. This approach has found use in select aerospace and automotive remanufacturing applications.

Are 3D printed parts currently suitable for any demanding applications?

Are 3D printed parts currently suitable for any demanding applications?

Yes, certain types of 3D printed parts are ideal for demanding applications. One example is General Electric, which uses additive manufacturing to produce a fuel injection nozzle for some of its jet engines. This extremely complex part is difficult and expensive to fabricate using traditional means.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act