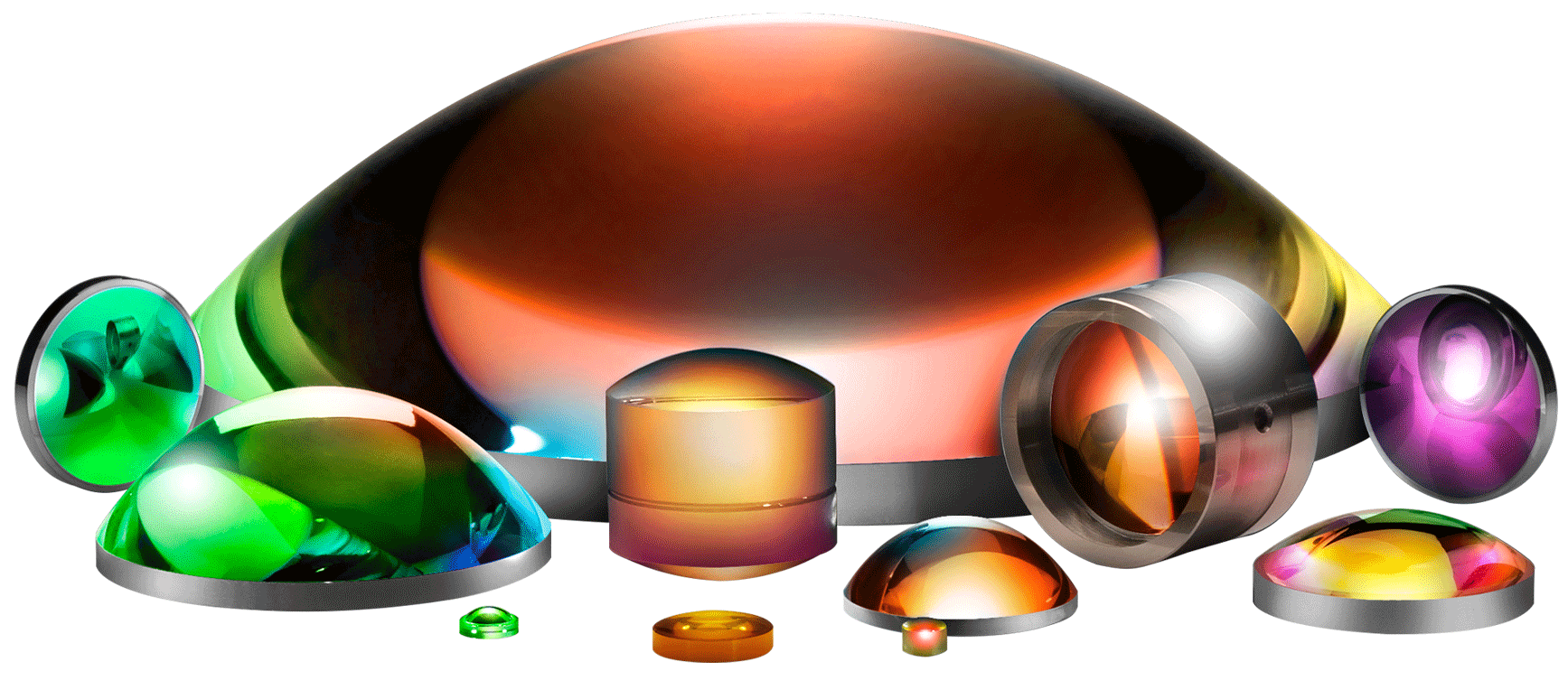

Edmund Optics® manufactures and supplies customers around the globe with millions of precision optical components and optical assemblies. Our manufacturing capabilities comprise of expertise and resources necessary to manufacture optical products based on your project’s specific requirements. Our dedicated and skilled team members will ensure that you receive the optimal solution for your application – from design support, to prototyping services, optical consulting all the way to volume production of your customized product to state-of-the-art metrology and quality assurance

Edmund Optics® takes customers from prototype to volume production specialized in creating cost-effective solutions that meet their specifications, timelines, and budgets.

Edmund Optics® continuously expands its equipment and toolset to optimize the fulfillment of our customer needs.

We have locations in 12 countries, 8 factories, 6 global warehouses, 4 world class design centers as well as 7 labs. With our global locations and local presence, we provide highly experienced application support by working directly with customers to find solutions for their unique parts and projects. Contact one of our in-region specialists, who have a wide range of customer and application experience to solve your unique application needs. If you do not find what you need, leverage our expertise for your next project – our team is passionate, dedicated, and committed to helping solve your challenges and design a customized solution. At Edmund Optics®, we do what is best for the customer.

77,000 sq. ft (7,150 m2) of manufacturing space. Highly vertically-integrated facility for volume production of components and mounted optics.

80,000 sq. ft (7,430 m2) of manufacturing space. High-precision spherical lenses, prisms, and other coated optics with over 50 years of experience.

120,000 sq. ft (11,150 m2); 20,000 sq. ft (1,860 m2) of dedicated manufacturing space. High-precision fabrication, coating, assembly, and testing cells.

34,000 sq. ft (3,159 m2)

dedicated to manufacturing high laser damage coatings, laser crystals, and other high-precision optics.

7,060 sq. ft (660 m2) facility. European manufacturing base for polarizers and colored filter glass and home for European Optical Design service.

16,140 sq. ft (1,500 m2) of manufacturing space. Supports Singapore facility in volume production of spherical lenses and prisms.

16,140 sq. ft (1,500 m2) of manufacturing space. On-site design, assembly, and testing of high volume optomechanical and imaging assemblies.

21,225 sq. ft (1,972 m2) facility for advanced, high-volume opto-electronic assembly, imaging optics design, and optical assembly metrology.

Optical coatings are a critical portion of the finished optical components or assembly. Accurate optical coating design and production can mean the difference between the component failing in the field or lasting for the intended lifetime of the project. Edmund Optics has extensive coating capabilities, and expertise in producing coatings for life science applications and medical devices, harsh environment imaging assemblies, and applications throughout the ultraviolet (UV), visible (VIS), and infrared (IR) spectral regions. All optics are meticulously cleaned, coated, and inspected in a clean room environment, and subjected to the environmental, thermal, and durability requirements specified by our customers.

Metrology is an essential step when delivering reliable customized products. If you can measure it, you can make it. We at Edmund Optics combine a wide range of metrology options and tools which can be used specifically for your needs, individually or in combination – your requirements define our process.

Every step of the way, Edmund Optics is commited to ensuring product and procedural quality and has a proven track record of tailored testing for optical assemblies customized to project requirements.

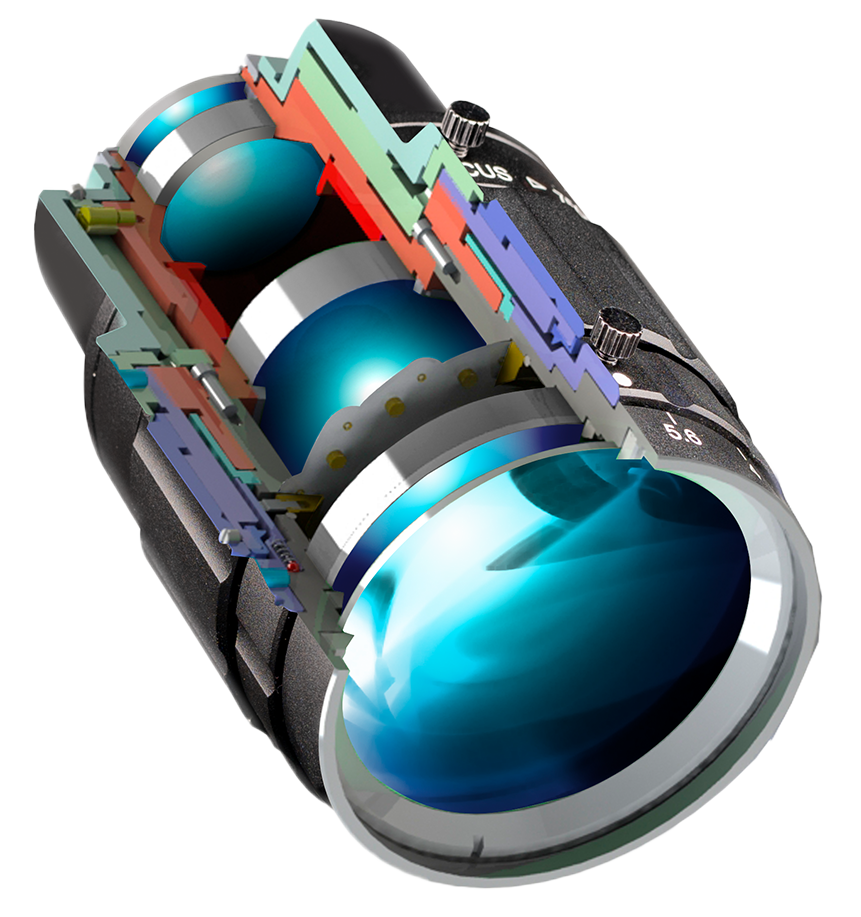

The expert team of Edmund Optics optical and optomechanical designers, project managers, and manufacturing engineers create a wide variety of different types of optomechanical assemblies.

Edmund Optics® engineers can design and manufacture fully-custom components, build-to-print following customer-supplied designs, and quickly modify any of our thousands of off-the-shelf optics sold in Edmund Optics® Marketplace.

Our in-house expertise and metrology to support your custom manufacturing spreads from Design, Consulting, via Prototyping to Testing.