|

|

Facilitates Manufacture of Optical Components with Complex Geometries |

|

|

Machine Wide Range of Materials that Cannot be Machined Through Conventional Methods |

|

|

Creates Specialty Counterbores, Bevels, Chamfers, Steps, Slots, and More |

|

|

More Repeatable than Conventional Manually Operated Machining |

Computer Numerical Control (CNC) machines are quickly gaining traction as indispensable tools for machining optical components with complex geometries. They are computer controlled electro-mechanical devices programmed with a machining language called “G-code,” and have numerous benefits over operator-required conventional machining. CNC machines offer the highest amount of precision, flexibility, and repeatability when it comes to fabricating components beyond basic shapes. CNC machining has been used for manufacturing metal and plastic parts for decades but is now pushing the boundaries of manufacturing glass and other optical materials. In addition to optical glass, CNC machining can be used to machine a wide range of demanding materials including ceramics, corundum, tungsten carbide, and even composites. Some of these advanced materials, such as Tungsten Carbide and composites, cannot be machined using conventional machining.

CNC machining offers numerous advantages over conventional grinding and polishing for fabricating optical components including:

24 Hour Operation

CNC machines have the ability to work 24 hours a day, 365 days a year, only needing to be switched off for maintenance or repair.

Complex Component Geometries

CNC machines are able to create components with complex geometries including bevels, deep holes, counterbores, chamfers, steps, slots, notches, and more. Even the most skilled operators using conventional machines cannot achieve the same precision and repeatability as CNC machines.

Limited Supervision Required

Fewer technicians are required to monitor the work of CNC machines compared to conventional methods because CNC machines are autonomous. Their autonomy allows for one person to watch several machines operate for hours on end after they have been programmed. The reduction of the number of technicians needed also reduces operating costs.

Repeatability

CNC machines have excellent repeatability because every component is manufactured following the same program. In conventional machining, even the most talented operators will produce components that vary slightly; this is not the case with CNC machines.

The main disadvantage of CNC glass machining is that the upfront cost of purchasing CNC machines is higher than that of conventional machines. More expensive equipment leads to higher prices for customers, but CNC glass machining can create intricate features with far more precision and repeatability than conventional equipment. CNC glass machining isn’t a cost effective method for making simple optics like spherical lenses and right angle prisms, but it is the ideal method for manufacturing components with complex geometries.

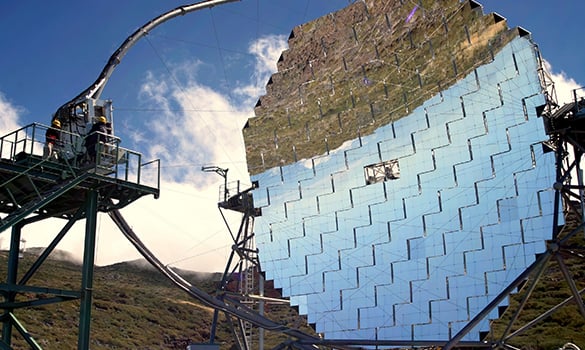

CNC machined precision optical components from EO are ideal for a wide variety of applications including advanced space telescopes and liquid chromatography systems.

Ultra-lightweight mirror substrates and other components with intricate cuts and bevels

Flow cells and other glass components with intricate channels and holes

Reference frames and cubes, wafer stages, high precision polygon mirrors, and more

Stabilized mirror substrates made from ZERODUR® and other advanced materials

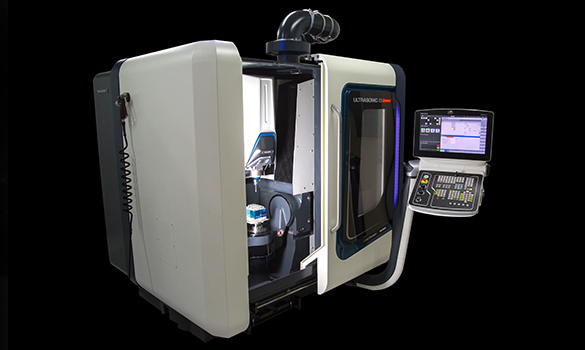

Edmund Optics® (EO) employs a wide range of CNC glass machining equipment to machine complex optical component geometries including ultrasonic machining and high speed cutting (HSC) technology from DMG MORI®. Our true 5-axis precision machine centers have the capability to machine lightweight structures and high aspect ratio components with specialty bevels, precision holes and inserts, and mounting interfaces. In addition to optical glass, we machine a wide range of demanding materials including ceramics, corundum, tungsten carbide, and even composites.

Visit our capabilities section to learn more about our CNC Glass Machining

What materials can Edmund Optics® machine using CNC equipment?

What materials can Edmund Optics® machine using CNC equipment?

What other types of CNC equipment does Edmund Optics® have besides the DMG MORI® ULTRASONIC 5-Axis Precision Machine Centers?

What other types of CNC equipment does Edmund Optics® have besides the DMG MORI® ULTRASONIC 5-Axis Precision Machine Centers?

In addition to DMG MORI® ULTRASONIC 5-Axis Precision Machine Centers, Edmund Optics® utilizes 5-Axis CNC Grinding Machines, 5-Axis CNC Polishing Machines, 3-Axis CNC Profiling Machines, 4-Axis CNC Slicing Machines, and 3-Axis CNC Milling Machines.

What are the largest size component(s) Edmund Optics® can manufacture using CNC equipment?

What are the largest size component(s) Edmund Optics® can manufacture using CNC equipment?

The maximum component diameter that Edmund Optics® can manufacture using our DMG MORI® ULTRASONIC 5-Axis Precision Machine Centers is 175mm.

Why hasn’t all optical manufacturing equipment been replaced with CNC machines?

Why hasn’t all optical manufacturing equipment been replaced with CNC machines?

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act