Homogeneity and Scatter from Inclusions and Bubbles

This is Sections 8.5 and 8.6 of the Laser Optics Resource Guide.

Homogeneity

The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront and polarizing transmission effects.1 This is defined as:

$\small{\Delta s}$ is the wavefront deviation, d is the substrate thickness, and $\small{\Delta n}$ is the P-V variation in refractive index. A high degree of homogeneity, or rather, a low degree of variation, is especially important for applications with high-powered lasers. Homogeneity variations develop from the processes in which the materials are melted. Improper mixing and thermodynamic imbalances induce density variations and the cooling and annealing processes can lead to strain profiles. Inhomogeneity takes the form of either global inhomogeneity, which is a refractive index variation across the entire piece of glass, or striae, which are spatially short-range variations of the homogeneity in a glass covering a distance of about 0.1mm up to 2mm. Table 1 shows defines the maximum refractive index variations of the common homogeneity classes.

| SCHOTT homogeneity class | ISO 10110 part 4 homogeneity class | Corning homogeneity class | Max. variation of refractive index according ISO 10110 part 4 |

| S0 | 0 | - | ±50 × 10-6 |

| S1 | 1 | - | ±20 × 10-6 |

| H1 | 1 | - | ±20 × 10-6 |

| H2 | 2 | F | ±5 × 10-6 |

| H3 | 3 | C | ±2 × 10-6 |

| H4 | 4 | A | ±1 × 10-6 |

| H5 | 5 | AA | ±0.5 × 10-6 |

Table 1: Classes of homogeneity and their maximum refractive index variation values2

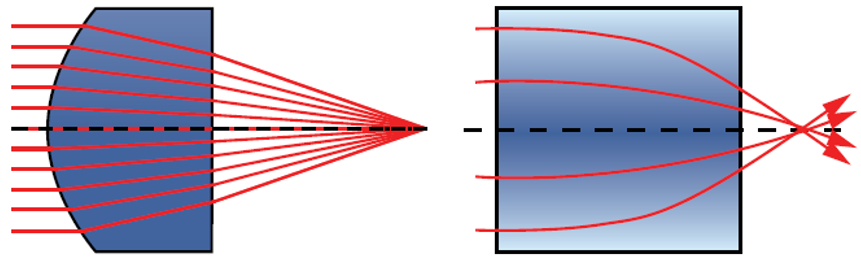

Graded-Index (GRIN) lenses are just one example of a type of lens that are intentionally non-homogeneous with a nonrandom and deterministic refractive index profile used to nonlinearly bend light rays (Figure 1).

Figure 1: Comparison of homogeneous lens and a GRIN lens focusing light to a point

Non-homogeneity causes scattering, which degrades system performance and could lead to laser-induced damage from high-power lasers. To prevent damage, as well as efficiently use energy, it is important for transmissive laser optics to be highly homogenous and thereby avoid deformation of the transmitted wavefront and polarizing transmission effects.

Scatter from Inclusions and Bubbles

Inclusions are foreign particles present in optical glass that are introduced in several ways including contamination during melting, substrate batches not melting completely, and wall materials featuring low solubility. Bubbles are also formed by reactions occurring in the glass melt. The bubbles are almost entirely removed during the refining step in glass melting, but some residual bubbles may be left behind from non-perfect refining. Sophisticated manufacturing processes ensure that optical glass is nearly free of inclusions and bubbles, but small amounts are unavoidable. In laser optics, inclusions reduce Laser Induced Damage Threshold (LIDT) due to light being scattered off the inclusions. The magnitude of the effect depends on the number, nature, and size of inclusions in the glass.

The concentration of inclusions and bubbles of a glass is given by the total cross section in mm2 of a 100cm3 volume of the material, calculated as the sum of the detected cross sections of bubbles and inclusions. The maximum allowable diameter and number of bubbles per 100cm3 volume is defined for each cross section. Inclusions are treated as bubbles of equivalent size. The three bubble classes include: standard, VB (increased bubble selection), and EVB (extra increased bubble selection):

| Standard | VB | EVB | |

|

Max. cross section in mm2 per 100cm3 of glass |

0.03 |

0.02 |

0.006 |

|

Maximum quantity per 100cm3 |

10 |

4 |

2 |

|

Standard |

VB |

EVB |

|

| Volume (cm3) | Max. allowable diameter of a single bubble (mm) | ||

| 800 | 0.55 | 0.45 | 0.25 |

| 500 | 0.44 | 0.36 | 0.20 |

| 300 | 0.34 | 0.28 | 0.15 |

| 200 | 0.28 | 0.23 | 0.12 |

| 100 | 0.20 | 0.16 | 0.09 |

| 50 | 0.14 | 0.11 | 0.06 |

Table 2: Classes of bubbles and inclusions in optical media3

| Corning inclusion class | Mass. cross section in mm2 per 100cm3 of glass | Max. inclusion size in mm |

| 0 | ≤0.03 | 0.10 |

| 1 | ≤0.10 | 0.28 |

| 2 | ≤0.25 | 0.50 |

Table 3: CORNING classes of inclusions in optical media

References

- F. Reitmayer and E. Schuster, "Homogeneity of Optical Glasses," Appl. Opt. 11, 1107-1111 (1972)

- “TIE-26: Homogeneity of Optical Glass.” Schott, February 2016.

- “TIE-28: Bubbles and Inclusions in Optical Glass.” Schott, May 2016.

Previous Section

Previous Section

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2023 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Act (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act